GRP (Glass Reinforced Plastic) pipe seals, also known as fiberglass pipe seals or GFRP (Glass Fiber Reinforced Plastic) pipe seals, are used in the construction and maintenance of GRP pipes. GRP pipes are made of a composite material consisting of glass fibers embedded in a resin matrix, which makes them lightweight, corrosion-resistant, and durable. Pipe seals designed for GRP pipes are essential components in ensuring the integrity and reliability of the pipe systems. Here are some key points about GRP pipe seals:

- Material Compatibility: GRP pipe seals are specifically designed to work with GRP pipes. The material used in these seals is chosen to be compatible with the GRP pipe’s properties, such as its corrosion resistance and durability.

- Sealing Function: The primary purpose of GRP pipe seals is to provide a reliable and leak-proof seal at various points in the GRP pipe system, including joints, connections, and fittings. This helps prevent fluid or gas leaks, ensuring the safety and efficiency of the pipeline.

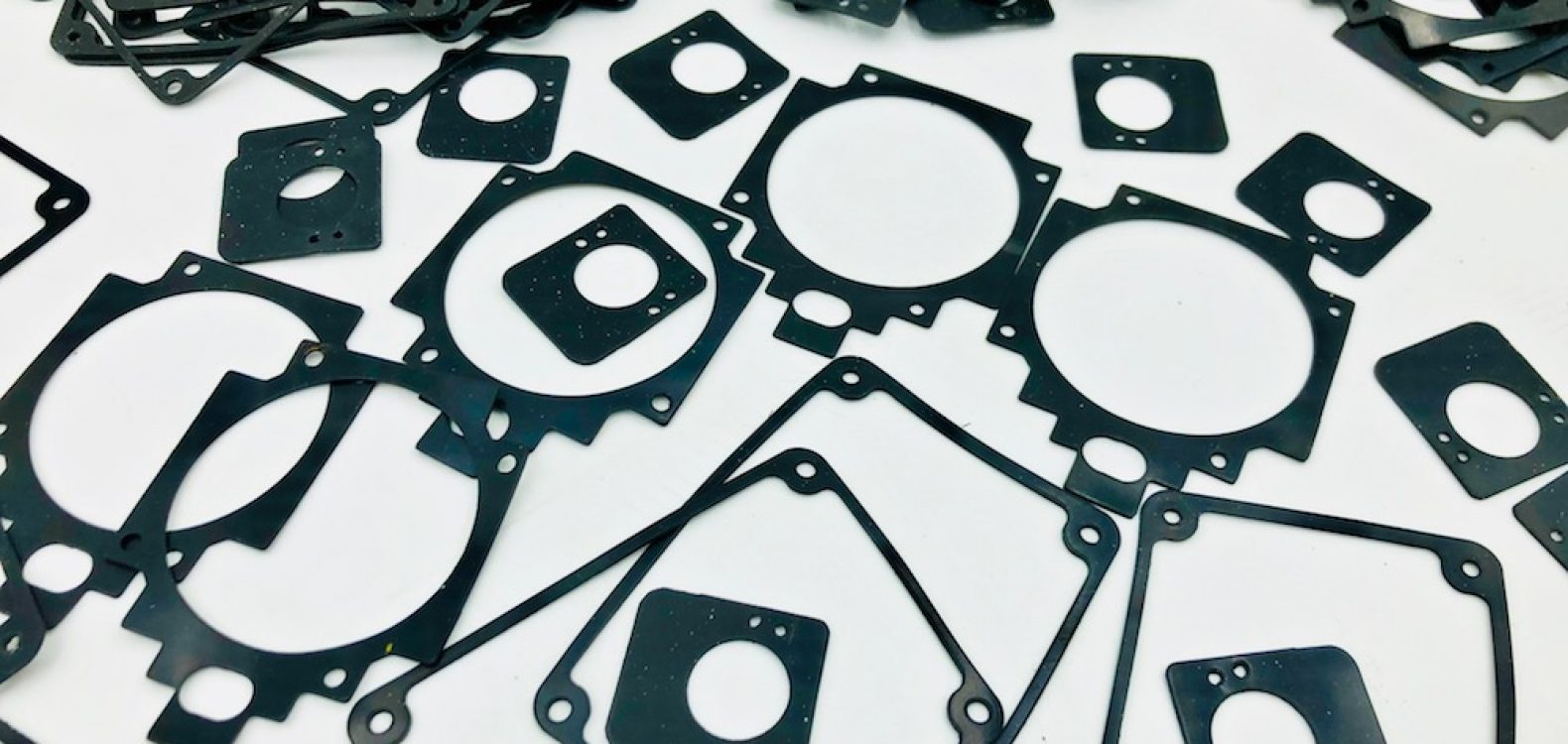

- Design Variability: GRP pipe seals come in various designs to suit different types of joints and connections used in GRP pipe systems. Some common types of seals include gaskets, O-rings, and custom-designed seals for specific applications.

- Chemical Resistance: GRP pipe seals are often exposed to a variety of chemicals and fluids, depending on the application. Therefore, these seals are typically designed to be chemically resistant to the specific substances they will come into contact with.

- Temperature and Pressure Tolerance: GRP pipe systems can operate under a range of temperatures and pressures. Pipe seals must be capable of withstanding these conditions without compromising their sealing properties.

- Durability: Since GRP pipes are known for their longevity, GRP pipe seals are expected to have a long service life as well. They should resist wear and tear over time, ensuring that the seal remains effective.

- Ease of Installation: Many GRP pipe seals are designed for easy installation, allowing workers to quickly and efficiently seal pipe joints and connections without the need for specialized tools or skills.

- Maintenance: Depending on the application, GRP pipe seals may require periodic inspection and maintenance to ensure they continue to provide an effective seal. This can include checking for signs of wear, damage, or degradation and replacing seals when necessary.

GRP pipe seals play a critical role in maintaining the integrity of GRP pipe systems, whether used in water and wastewater treatment plants, chemical processing facilities, industrial applications, or other environments. Choosing the right type of seal and ensuring proper installation is essential for the long-term performance and safety of the piping system. Manufacturers of GRP pipe seals typically provide guidelines and recommendations for their use and maintenance.