Aluminum rubber seals, also known as aluminum-rubber gaskets or aluminum rubber weatherstripping, are specialized sealing components typically used in various industrial, automotive, and construction applications. These seals are designed to provide a secure and durable seal between two surfaces while offering resistance to environmental factors, such as temperature fluctuations, moisture, dust, and even some chemicals. Here’s a comprehensive description of aluminum rubber seals:

Composition and Structure:

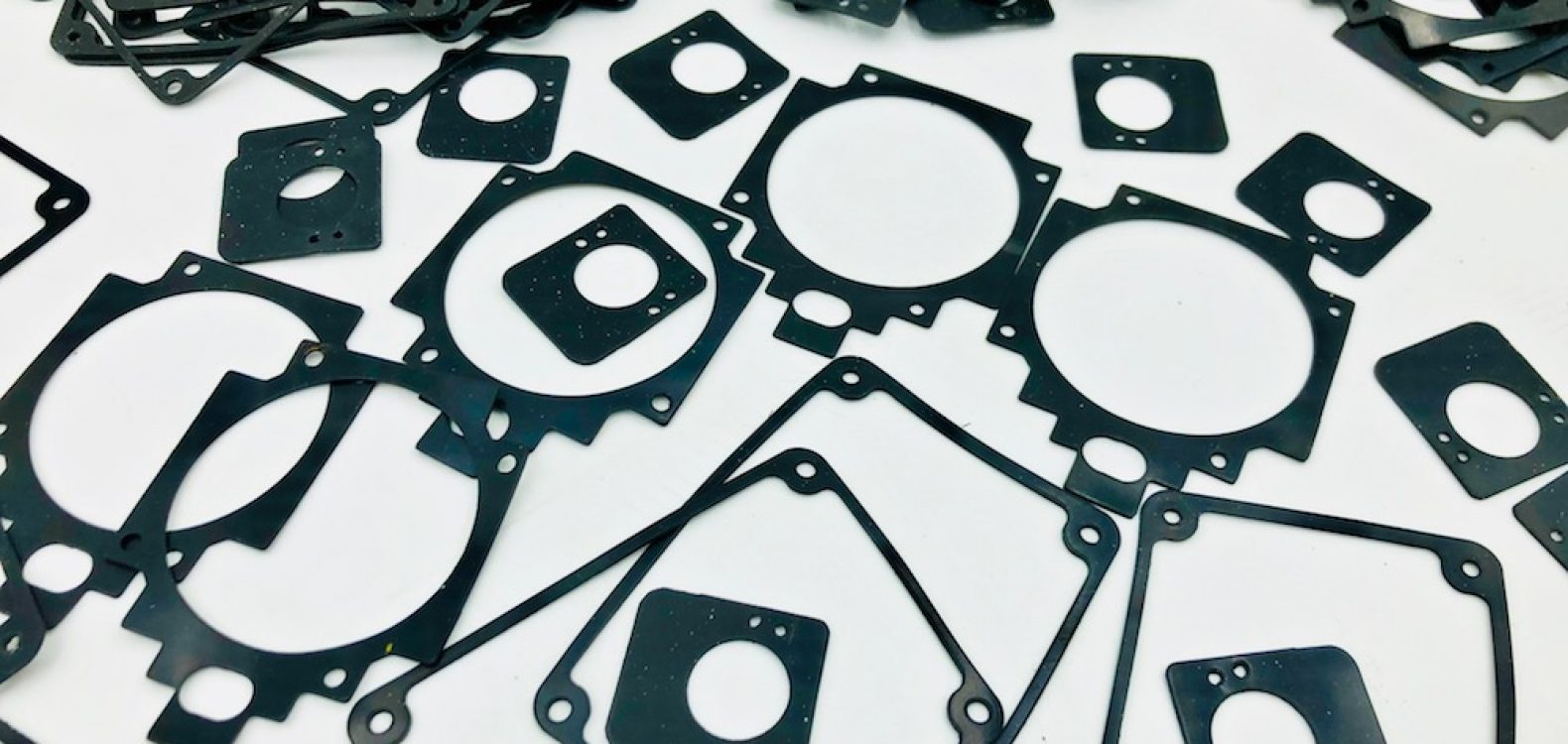

Aluminum rubber seals are composed of two primary materials: aluminum and rubber. The aluminum component often forms the rigid or semi-rigid part of the seal, providing structural support and stability. The rubber component is typically made from synthetic elastomers like EPDM (ethylene propylene diene monomer) or silicone rubber, known for their excellent sealing properties, flexibility, and resistance to environmental factors.

Key Characteristics:

- Sealing Capability: The rubber portion of these seals is responsible for creating an effective and long-lasting seal, preventing the passage of air, water, dust, or other contaminants between the sealed surfaces.

- Versatility: Aluminum rubber seals are versatile and adaptable to a wide range of applications. They can be customized in various shapes and sizes to fit specific sealing requirements.

- Durability: The combination of aluminum and rubber makes these seals durable and resistant to wear and tear, ensuring a long service life.

- Temperature Resistance: They can withstand a broad temperature range, from extreme cold to high heat, without losing their sealing effectiveness.

- Chemical Resistance: Depending on the type of rubber used, these seals can also offer resistance to various chemicals and oils, making them suitable for applications in industrial settings.

Common Applications:

Aluminum rubber seals find application in various industries and sectors, including:

- Automotive: They are used in vehicle doors, windows, trunks, and hoods to create weather-tight seals, reduce noise, and enhance overall comfort.

- Construction: These seals are employed in doors, windows, and curtain walls of buildings to prevent air and water infiltration, ensuring energy efficiency and interior comfort.

- Industrial Equipment: They are used in machinery, equipment enclosures, and access panels to maintain environmental seals and protect sensitive components.

- Aerospace: In the aerospace industry, they are used for sealing applications in aircraft doors, windows, and hatches.

- Electronics: Aluminum rubber seals are utilized in electronic enclosures to protect sensitive electronic components from environmental factors.

Installation and Maintenance:

Installation of aluminum rubber seals typically involves fitting them into grooves or channels designed to accommodate the seal. Proper installation ensures an effective and secure seal. Maintenance may involve periodic inspections to check for wear, damage, or deterioration, with damaged seals replaced as needed to maintain their functionality.

In summary, aluminum rubber seals are versatile sealing components with a combination of aluminum and rubber, providing durability, weather resistance, and versatility across various industries. They play a crucial role in maintaining environmental seals, ensuring energy efficiency, and enhancing the performance and longevity of numerous applications. Proper installation and maintenance are essential for their continued effectiveness.