EPDM (ethylene propylene diene monomer) rubber seals are widely used in various industries and applications for their excellent sealing properties, durability, and resistance to environmental factors. These seals are made from EPDM rubber, a synthetic elastomer known for its versatility and reliability. Here’s a detailed description of EPDM rubber seals:

Composition and Structure:

- EPDM Rubber: EPDM is a synthetic rubber compound composed of ethylene, propylene, and diene monomers. It is characterized by its exceptional resistance to UV radiation, ozone, weathering, and a wide range of environmental conditions.

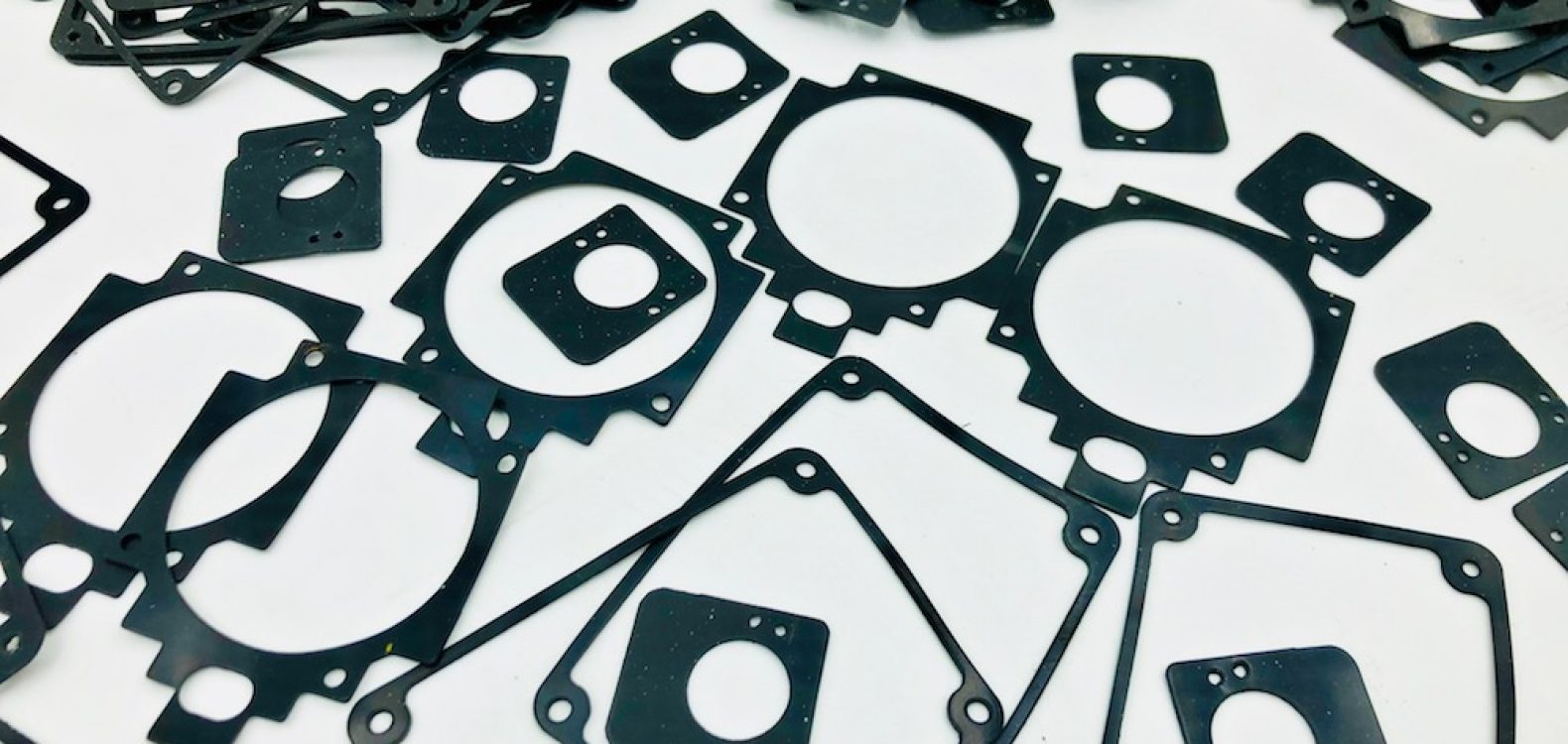

- Seal Design: EPDM rubber seals come in a variety of shapes and sizes, depending on their intended application. They can be designed as O-rings, gaskets, extruded profiles, or molded parts. The design may incorporate specialized features such as ridges, lips, or grooves to enhance their sealing capabilities.

Key Characteristics:

- Weather Resistance: EPDM rubber seals are highly resistant to outdoor weather conditions, including sunlight, rain, and temperature fluctuations. They do not degrade or become brittle when exposed to UV radiation, making them suitable for outdoor and exposed applications.

- Excellent Sealing Properties: EPDM rubber offers excellent compression set resistance, which means it can maintain a tight and reliable seal even after repeated compression and release. This property makes it effective in preventing the leakage of liquids, gases, or air.

- Temperature Tolerance: EPDM rubber seals can withstand a broad temperature range, from -40°C (-40°F) to 150°C (302°F), making them suitable for both hot and cold environments.

- Chemical Resistance: EPDM rubber is resistant to a wide range of chemicals, acids, and alkalis, making it suitable for use in applications where exposure to corrosive substances is a concern.

- Flexibility and Elasticity: EPDM rubber is flexible and elastic, allowing it to conform to irregular surfaces and maintain a reliable seal even in challenging conditions.

Applications:

EPDM rubber seals are utilized in various industries and applications, including:

- Automotive: EPDM rubber seals are used in automotive applications, such as door seals, window seals, gaskets, and hoses, to provide weatherproofing, noise reduction, and sealing functions.

- Construction: They are employed in construction for sealing windows, doors, curtain walls, roofing systems, and expansion joints, ensuring that buildings remain weather-tight, energy-efficient, and structurally sound.

- Electrical and Electronics: EPDM rubber seals are used in electrical enclosures, gaskets, and cable seals to create dustproof and waterproof seals, protecting sensitive equipment from environmental factors.

- HVAC (Heating, Ventilation, and Air Conditioning): EPDM rubber gaskets are used in HVAC systems to seal air ducts, access panels, and other components, preventing air leakage and improving energy efficiency.

- Marine: In the marine industry, EPDM rubber seals are used for sealing hatches, portholes, doors, and other openings to maintain watertight integrity in boats and ships.

- Industrial Equipment: EPDM rubber seals are used in a wide range of industrial equipment, including pumps, valves, and machinery, to prevent leaks and ensure efficient operation.

Installation and Maintenance:

Installing EPDM rubber seals typically involves placing them in the designated groove or channel, ensuring that they fit securely and form a proper seal. Maintenance may involve periodic inspections to check for wear, damage, or deterioration, with damaged seals replaced as needed to maintain their sealing effectiveness.

In summary, EPDM rubber seals are versatile and dependable sealing components known for their weather resistance, durability, and sealing capabilities. They play a crucial role in various industries and applications, ensuring the integrity and performance of a wide range of products and systems. Proper installation and maintenance are essential to maximize their effectiveness and longevity.