Dilatation seals, also known as expansion joints or expansion seals, are specialized engineering components used in various industries to accommodate dimensional changes in structures, machinery, and systems due to thermal expansion, contraction, vibration, seismic activity, settling, or other dynamic forces. These seals are designed to provide a flexible and resilient connection between two adjacent components, allowing them to move independently while maintaining a seal or connection.

The primary purpose of dilatation seals is to prevent damage and maintain the integrity of structures and systems by effectively managing the movement and displacement that can occur under various conditions. Here’s a more detailed explanation of their characteristics and applications:

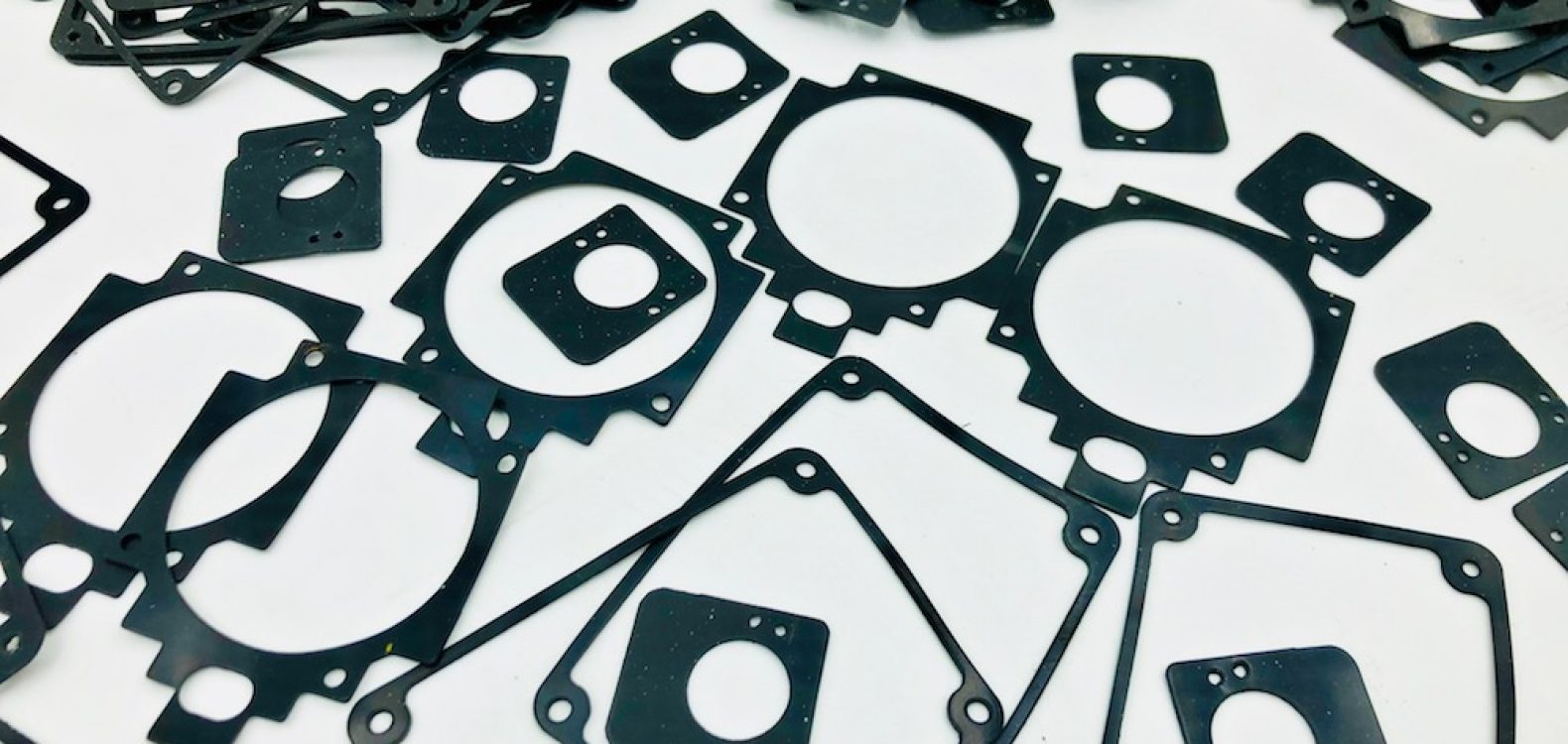

- Design and Structure: Dilatation seals are typically constructed using a combination of flexible materials such as rubber, neoprene, PTFE (polytetrafluoroethylene), or metal components. The choice of materials depends on the specific application, environmental factors, and the magnitude of movement that needs to be accommodated.

- Types of Dilatation Seals:

- Rubber Expansion Joints: These are made of various rubber compounds and are suitable for absorbing small to moderate movements, making them common in HVAC systems and pipelines.

- Metal Expansion Joints: These consist of multiple metal bellows that can handle high-pressure applications and greater movements, often found in industrial piping systems and power plants.

- PTFE Expansion Joints: Made of polytetrafluoroethylene, these are known for their chemical resistance and are used in corrosive environments.

- Applications:

- Buildings: Dilatation seals are used in construction to bridge gaps between building sections, accommodating expansion and contraction caused by temperature fluctuations and structural movement.

- Pipelines: In the oil and gas industry and water distribution systems, they prevent damage and leakage by compensating for the movement and vibration of pipelines.

- Industrial Equipment: In manufacturing facilities, they are employed in machinery, ductwork, and conveyors to absorb vibrations and thermal expansion.

- Bridges and Infrastructure: Expansion joints are essential for bridges and highways to handle the expansion and contraction of concrete and steel structures.

- Benefits:

- Preventing Structural Damage: Dilatation seals protect structures and systems from potential damage due to thermal expansion, seismic activity, or other dynamic forces.

- Enhanced Safety: They improve the overall safety of infrastructure by reducing the risk of structural failures or leakages.

- Longevity: Properly designed and maintained dilatation seals can significantly extend the lifespan of various components and systems.

- Installation and Maintenance:

- Dilatation seals require careful installation to ensure they function effectively.

- Regular inspections and maintenance are crucial to detect wear, tear, or damage and replace seals as necessary.

In summary, dilatation seals are essential engineering components that provide flexibility and protection to structures and systems by accommodating movements and changes in their dimensions. Their design and material selection depend on the specific application and the level of movement they need to handle, making them versatile solutions in a wide range of industries. Proper installation and maintenance are essential to ensure their continued effectiveness and the safety and integrity of the systems they protect.