Concrete pipe seals, also known as pipe gaskets or concrete pipe gasket seals, are essential components used in the construction and maintenance of concrete pipes and pipelines. These seals are designed to create a watertight and secure connection between individual concrete pipe sections or between concrete pipes and other pipeline components. Here’s a detailed description of concrete pipe seals:

Types of Concrete Pipe Seals:

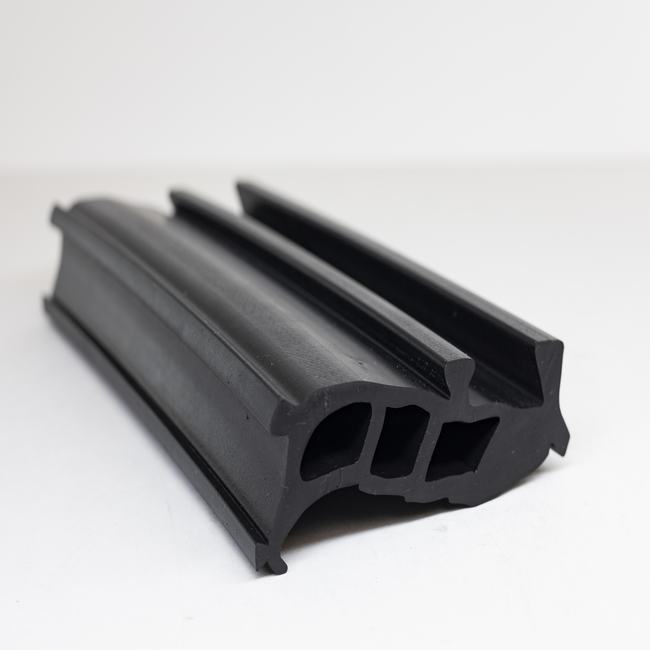

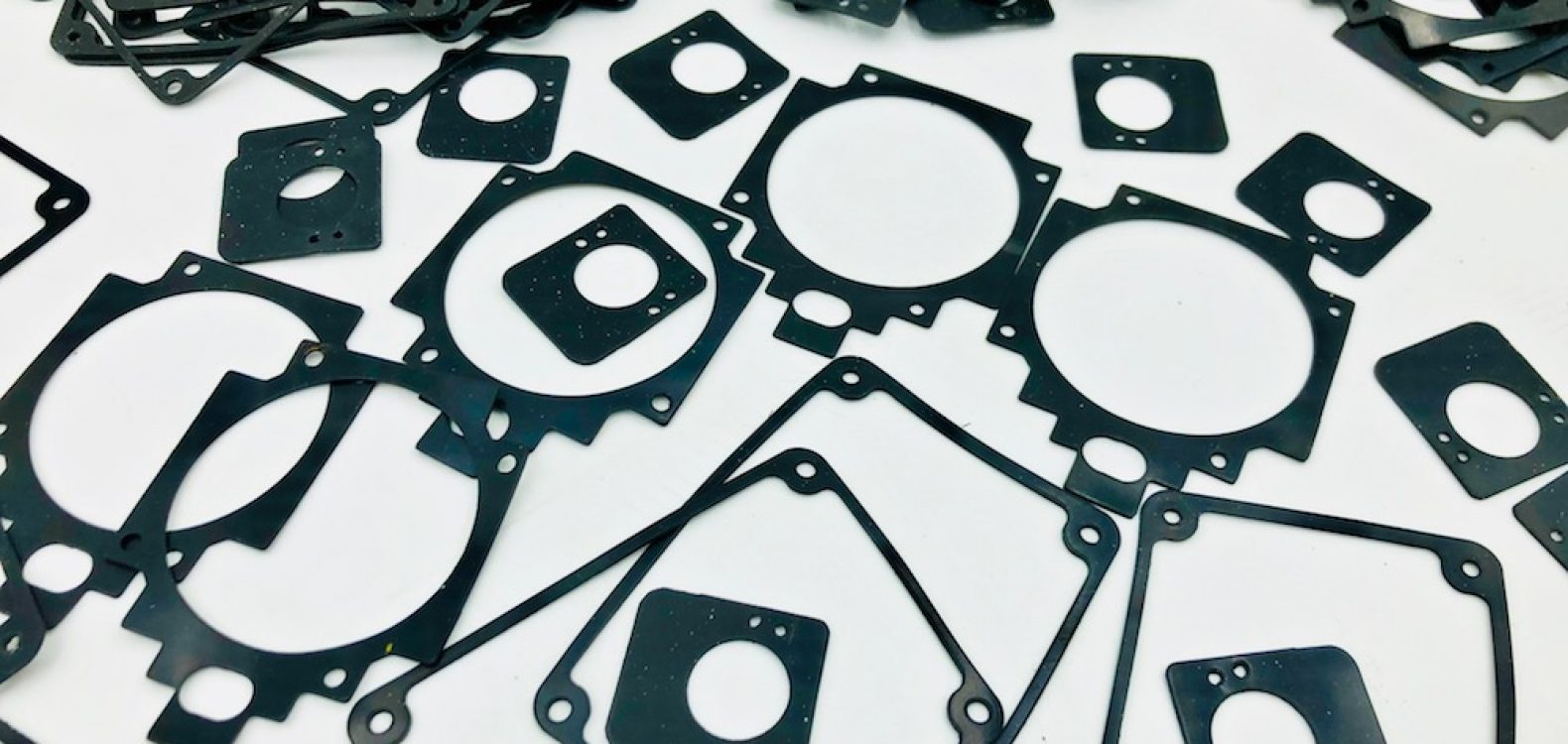

- Rubber Gaskets: Rubber gaskets are the most common type of concrete pipe seals. They are typically made from high-quality rubber compounds, such as EPDM (ethylene propylene diene monomer) or neoprene, which provide excellent sealing properties and resistance to environmental factors.

- Joint Wraparound Seals: These seals are used to create a watertight seal at the joint between two concrete pipe sections. They wrap around the joint and are secured in place to prevent water infiltration.

- O-Ring Seals: O-ring seals are typically used in circular or bell-and-spigot pipe connections. They are circular rubber seals with a cross-sectional O-shaped profile that fits into a groove or recess in the pipe joint, ensuring a secure and watertight seal.

Key Characteristics:

- Watertight Seal: The primary function of concrete pipe seals is to create a watertight seal, preventing the leakage of liquids, including sewage, stormwater, or industrial fluids, from the pipe joint.

- Durability: Concrete pipe seals are designed to withstand long-term exposure to moisture, chemicals, and varying temperatures without degradation or loss of sealing effectiveness.

- Easy Installation: They are relatively easy to install during the construction or maintenance of concrete pipelines. The seals are placed in the joint or groove, and the pipe sections are then connected, compressing the seal to create a tight seal.

- Resilience: These seals are resilient and can accommodate movement, settlement, and minor misalignments in the concrete pipe sections, ensuring a continuous and effective seal.

Applications:

Concrete pipe seals are used in a variety of applications, including:

- Sanitary Sewer Systems: They are employed in sanitary sewer pipelines to prevent the leakage of wastewater and sewage, ensuring the protection of public health and the environment.

- Stormwater Management: Concrete pipe seals are used in stormwater drainage systems to manage rainwater runoff and prevent water from infiltrating the ground and causing erosion or flooding.

- Water Supply Systems: In potable water distribution systems, specialized gaskets and seals that meet drinking water quality standards are used to maintain water quality and prevent contamination.

- Industrial Pipelines: These seals are used in industrial settings for the transportation of various liquids, including chemicals, slurries, and industrial wastewater.

Installation and Maintenance:

Installing concrete pipe seals involves placing the gaskets in the designated grooves or joints before connecting the concrete pipe sections. Proper alignment and compression are crucial to ensure an effective seal.

Maintenance of concrete pipe seals typically involves periodic inspections to check for wear, damage, or deterioration. Damaged or worn seals should be replaced promptly to maintain the integrity of the pipeline and prevent leaks.

In summary, concrete pipe seals are critical components in the construction and maintenance of concrete pipelines, providing a watertight and durable seal that is essential for the effective transportation of liquids and the protection of the environment. Their ease of installation, durability, and resilience make them indispensable in a wide range of applications. Proper installation and regular maintenance are essential for their long-term performance.